January 03, 2026 Procurement Insights

Why Artwork Approval Windows Expand Beyond Supplier Timelines in Custom Drinkware Orders

Overview

Factory project managers explain why the 3-day proof delivery promise becomes a 23-day approval window when multi-stakeholder workflows and revision cycles are factored into custom drinkware lead time calculations.

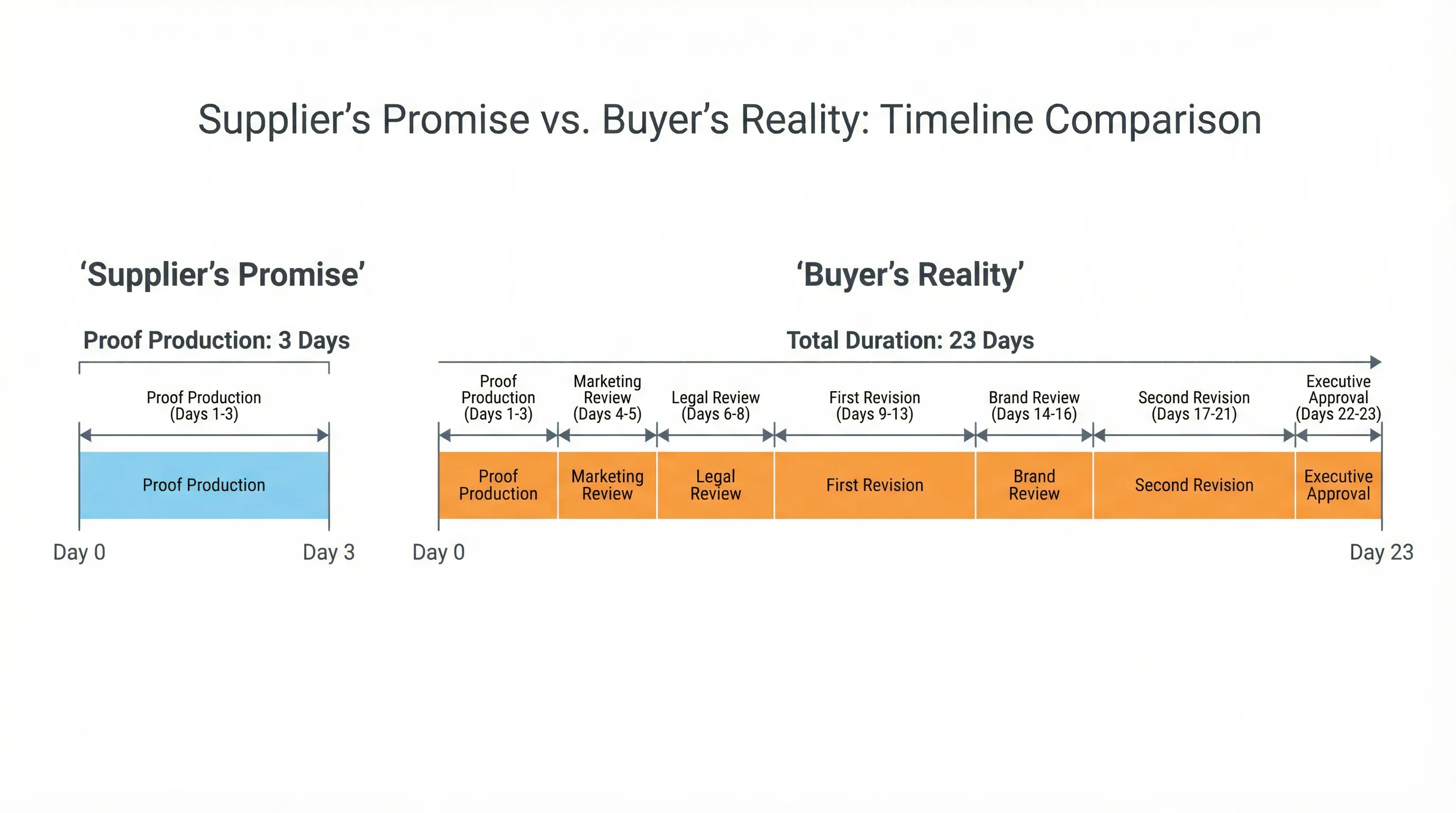

When a supplier quotes "three business days for proof delivery," buyers often interpret this as the total artwork approval window. In practice, this is where lead time calculations start to diverge from reality. The three days represent only the supplier's internal proof production time—not the buyer's internal approval workflow, not the revision cycles that follow, and certainly not the cumulative delay when feedback arrives incrementally rather than in batches.

Working as a factory project manager coordinating custom drinkware orders between Asian manufacturers and New Zealand enterprises, I have observed a consistent pattern: buyers allocate approximately four to five days for the entire artwork approval phase in their timeline planning, yet the actual approval window extends to eighteen to twenty-three days on average. This discrepancy is not caused by supplier delays or shipping disruptions. It originates from a structural misunderstanding of what "artwork approval" actually entails when multiple stakeholders must coordinate across legal, brand, and executive review layers.

The issue manifests most clearly in mid-sized corporate orders—typically five thousand to ten thousand units of custom vacuum bottles or thermal tumblers—where brand consistency requirements demand rigorous approval protocols, yet procurement teams lack dedicated artwork coordinators. These buyers receive the supplier's digital proof via email, forward it to the marketing department, and assume the approval will return within twenty-four to forty-eight hours. What they fail to account for is that marketing cannot approve artwork unilaterally. The proof must route through legal review to confirm trademark usage compliance, brand team review to verify Pantone color accuracy and logo placement, and executive sign-off to authorize the expenditure. Each handoff introduces a two-to-three-day delay, even when no revisions are requested.

The situation compounds when revisions become necessary. Suppliers typically require three to five working days to produce a revised proof—this includes adjusting the artwork file, generating a new digital mockup, and in some cases, producing a physical sample that must be couriered from Guangzhou to Auckland. If the buyer's legal team identifies a trademark issue on day eight of the approval process and requests a logo modification, the revised proof will not arrive until day thirteen at the earliest. If the brand team then discovers that the powder coating color does not match the specified Pantone code and requests a second revision, the timeline extends to day eighteen. By the time the executive reviews and approves the third proof on day twenty-three, the "four-day artwork approval window" has consumed nearly a month of the project schedule.

This timeline expansion is rarely visible to procurement teams because it sits outside the metrics suppliers report. When a factory states "production lead time is thirty-five working days," that figure begins only after proof approval is finalized. The eighteen-to-twenty-three-day approval window precedes this production phase, yet buyers consistently exclude it from their total lead time calculations. For enterprises planning custom drinkware orders around specific event dates—such as a product launch in Wellington or a corporate conference in Christchurch—this miscalculation directly translates into missed deadlines. The bottles arrive in perfect condition, but three weeks after the event has concluded.

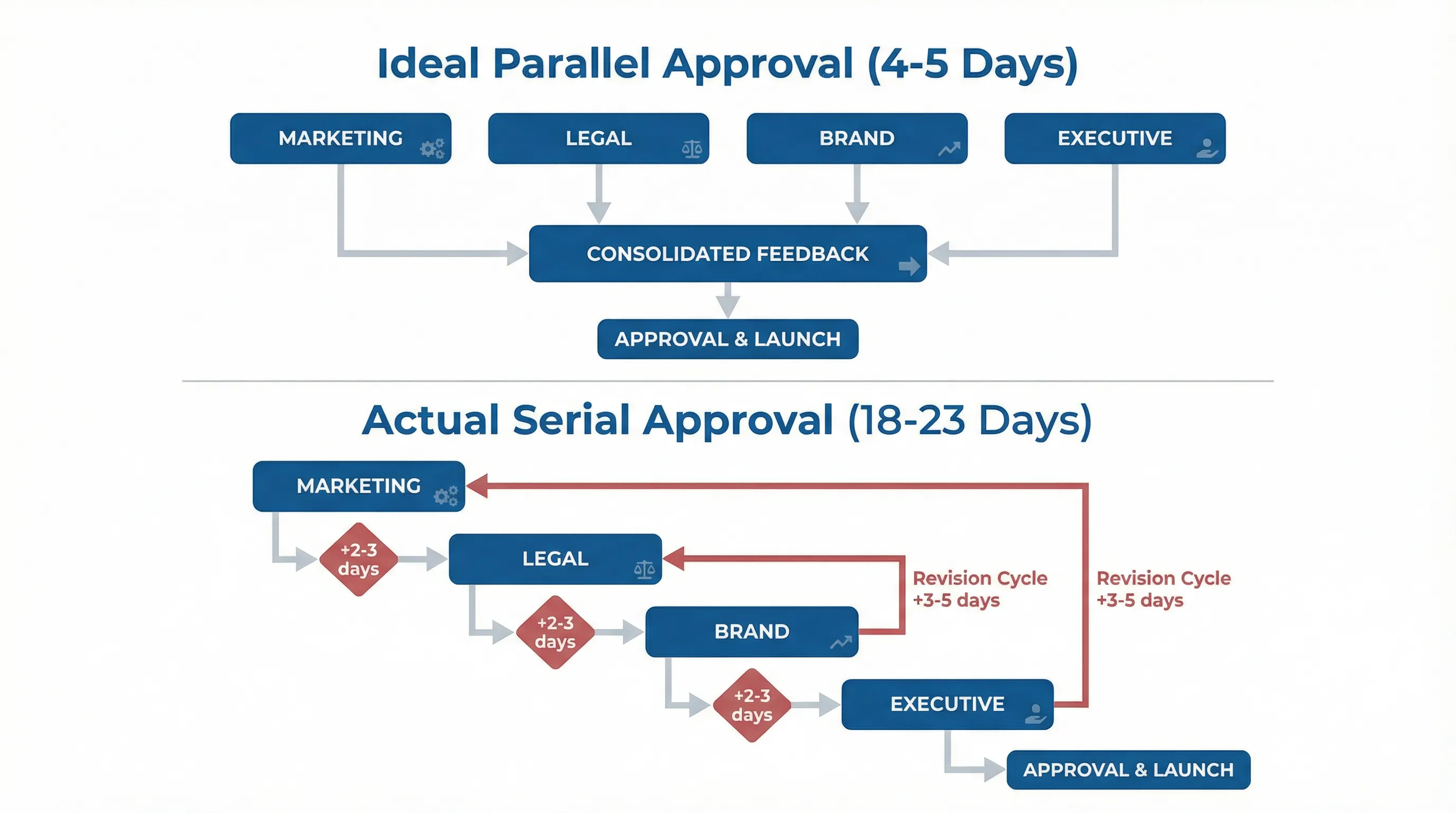

The root cause is not that buyers are careless. It is that the approval workflow operates as a serial process disguised as a parallel one. Marketing receives the proof first, reviews it, and forwards it to legal. Legal reviews it and forwards it to the brand team. The brand team reviews it and forwards it to the executive. Each department operates independently, unaware that their two-day review window is being multiplied by four sequential handoffs. If any single stakeholder requests a revision, the entire sequence restarts from the beginning. This is fundamentally different from how buyers conceptualize "approval"—which they envision as a single decision point rather than a multi-stage workflow with compounding delays.

The second structural issue is feedback batching failure. In an ideal approval process, all stakeholders review the proof simultaneously, consolidate their feedback into a single revision request, and send it to the supplier in one batch. This approach minimizes revision cycles and allows the factory to address all changes in a single iteration. In practice, feedback arrives incrementally. Marketing approves the proof on day five, then legal identifies a compliance issue on day eight, then the brand team discovers a color mismatch on day thirteen, and finally the executive requests a minor logo adjustment on day eighteen. Each piece of feedback triggers a separate revision cycle, extending the timeline by three to five days per iteration. The cumulative effect is that four separate feedback points—each individually minor—generate twelve to twenty days of delay.

This incremental feedback pattern is not intentional. It occurs because buyers lack a structured mechanism to collect and consolidate stakeholder input before forwarding it to the supplier. Marketing forwards the proof to legal as soon as they finish their own review, rather than waiting for legal to complete their assessment before sending both sets of feedback together. Legal forwards the proof to the brand team immediately after identifying their compliance concern, rather than coordinating with the brand team to submit a combined revision request. The result is a cascading series of small delays that aggregate into a timeline overrun large enough to jeopardize the entire project schedule.

Auckland enterprises ordering five thousand custom stainless steel bottles for a mid-year corporate event typically allocate fifty-five to sixty working days for the complete procurement cycle, based on the supplier's quoted "thirty-five-day production lead time" plus fifteen days for sea freight and five days for artwork approval. When the artwork approval phase extends to twenty-three days instead of five, the total timeline reaches seventy-three days—exceeding the planned window by nearly three weeks. If the buyer initiated the order ten weeks before the event date, assuming this provided adequate buffer time, they will discover on week nine that the bottles will not arrive until week eleven. At this stage, switching to air freight can compress the shipping window from fifteen days to five days, but air freight costs approximately eight to twelve New Zealand dollars per kilogram compared to one-fifty to two-fifty per kilogram for sea freight. For a five-thousand-unit order of bottles weighing three hundred fifty grams each, the freight cost difference exceeds ten thousand dollars—a premium that could have been avoided entirely if the artwork approval timeline had been calculated accurately from the outset.

The challenge for procurement teams is that this approval window expansion is invisible until it has already occurred. Suppliers do not track the buyer's internal approval workflow, so they cannot provide advance warning when delays are accumulating. Marketing departments do not report their handoff timelines to procurement, so buyers remain unaware that the proof has been sitting in legal review for four days. By the time procurement realizes the approval phase is running behind schedule, the delay has already consumed the buffer time built into the project plan. Enterprises that understand production timelines for custom drinkware recognize that pre-production phases—including artwork approval—require as much planning rigor as the manufacturing window itself.

The solution is not to pressure stakeholders to approve proofs faster. Legal review cannot be rushed without introducing compliance risk, and brand team review cannot be compressed without sacrificing color accuracy and logo placement precision. The solution is to restructure the approval workflow so that feedback is collected in parallel rather than in series, and to allocate eighteen to twenty-three days for the artwork approval phase in the initial timeline planning rather than four to five days. Buyers who implement this adjustment discover that their lead time calculations align with reality, their event deadlines are met consistently, and their freight cost premiums disappear because they no longer need to resort to air shipping to compensate for timeline miscalculations.

For New Zealand enterprises planning custom drinkware orders, the artwork approval window is not a minor administrative step. It is a critical phase that consumes twenty to thirty percent of the total lead time, yet remains systematically underestimated in procurement planning. Recognizing this discrepancy and adjusting timeline calculations accordingly is the difference between receiving branded bottles three weeks before an event and receiving them three weeks after.