January 08, 2026 Procurement Insights

Why Multi-Location Delivery Requests Extend Custom Drinkware Production Timelines

Overview

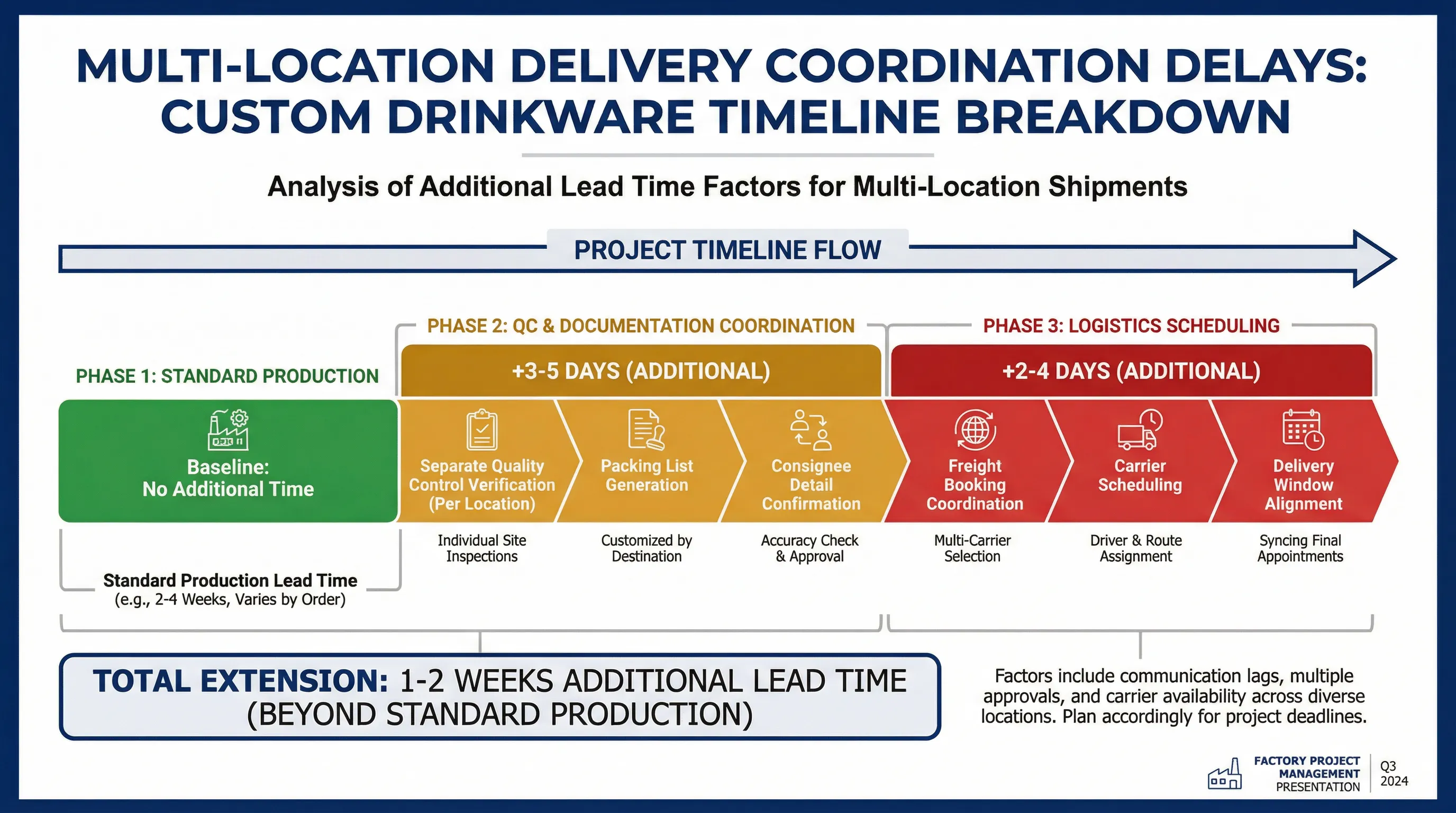

Factory project managers explain why requesting delivery to three separate offices transforms a single 10,000-unit order into three separate fulfillment projects that extend lead times by 1-2 weeks beyond standard production schedules.

When procurement teams place a single purchase order for 10,000 custom water bottles and request delivery to three separate offices—2,000 units to the Auckland headquarters, 3,000 to the Wellington branch, and 5,000 to the Christchurch distribution centre—they typically view this as a straightforward shipping instruction. The assumption is that the factory produces all 10,000 units as one batch, and the logistics provider simply splits the shipment at the final mile. In practice, this is often where lead time estimates start to diverge from reality. What appears to be a single order on the buyer's purchase requisition transforms into three separate fulfillment projects on the factory floor, each requiring independent quality control verification, packing list generation, carton labeling, and logistics coordination. The additional lead time required for this coordination—typically one to two weeks—is rarely factored into the buyer's delivery expectations, because the decision to split delivery across multiple locations is made after the production timeline has already been communicated.

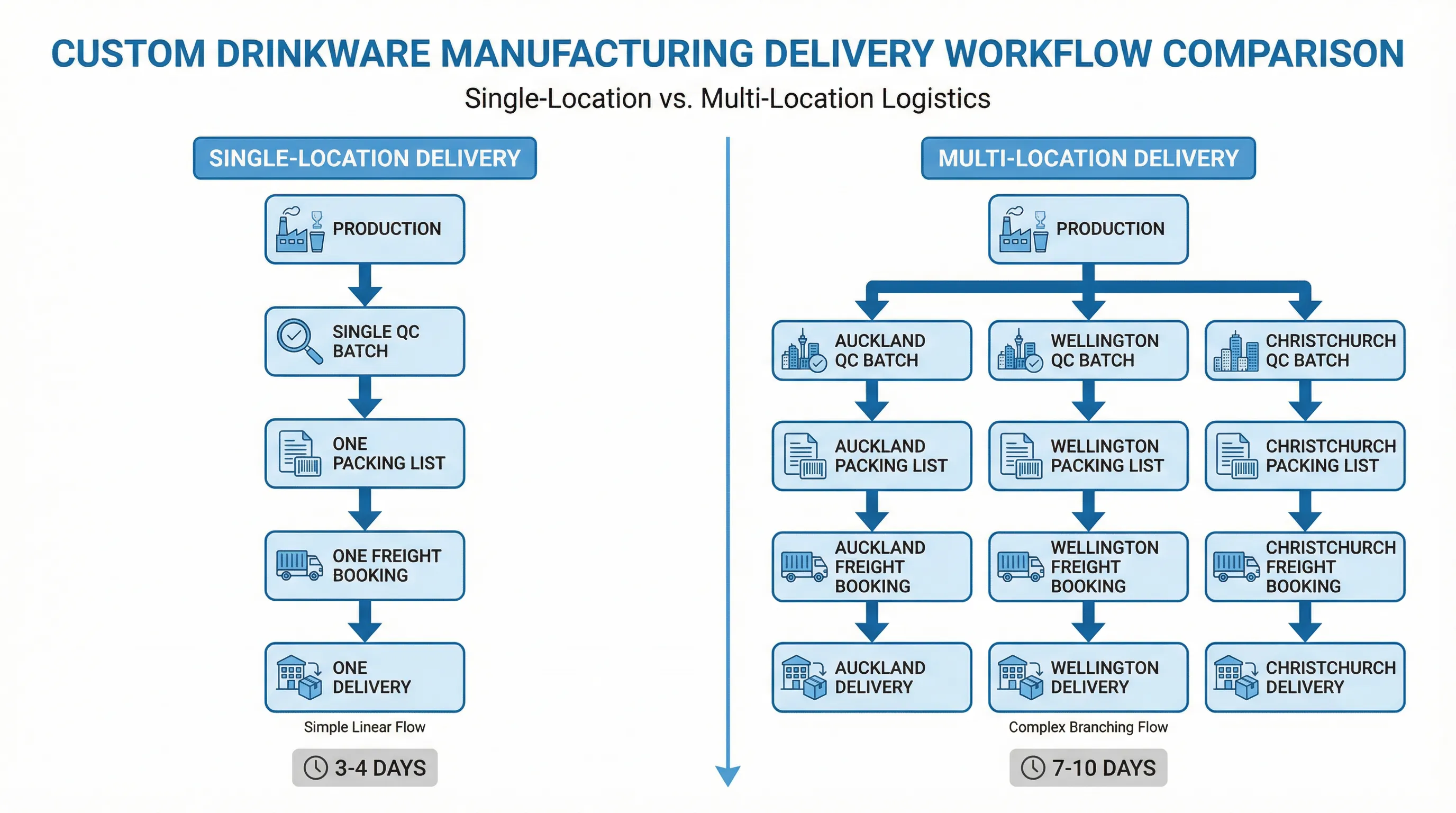

The core issue is not the physical act of shipping to multiple addresses. Modern freight forwarders handle multi-destination logistics routinely. The problem lies in how multi-location delivery affects the factory's internal workflow during the final stages of production. When a single-destination order reaches the quality control phase, the factory conducts batch sampling: a statistically representative sample is drawn from the entire production run, inspected for defects, and if the sample passes, the entire batch is cleared for packing. The packing process is similarly streamlined—one master packing list is generated, cartons are labeled with a single consignee address, and the entire shipment is palletized for a single freight booking. This process typically takes three to four days for a 10,000-unit order. However, when the same order must be split into three separate deliveries, the factory cannot simply divide the finished goods into three piles and ship them. Each destination-specific batch must be treated as an independent fulfillment, because each batch will be received, inspected, and potentially disputed by a different party at a different location. This means the factory must conduct separate quality control verification for each batch to ensure that the Auckland shipment, the Wellington shipment, and the Christchurch shipment all meet the same quality standard. If a defect is discovered in the Christchurch batch after it has been shipped, the factory cannot simply point to the fact that the Auckland and Wellington batches passed inspection—the buyer will rightfully argue that each location should have received goods of consistent quality.

The quality control implications are compounded by the packing and documentation requirements. A single-destination order requires one commercial invoice, one packing list, and one set of carton labels. A three-destination order requires three separate commercial invoices (because each consignee may have different billing arrangements), three separate packing lists (because each warehouse will need to verify the contents of their specific shipment), and three separate sets of carton labels (because mislabeling a carton destined for Wellington with a Christchurch address creates a logistics failure that the factory will be held responsible for). Generating these documents is not merely an administrative task—it requires the factory's project manager to coordinate with the buyer to confirm the exact unit allocation for each location, verify the consignee details for each address, and ensure that any location-specific instructions (such as "Wellington delivery must arrive before 3 PM due to warehouse closing hours") are captured in the shipping documentation. This coordination process typically adds three to five days to the lead time, because it involves back-and-forth communication between the factory, the buyer's procurement team, and potentially the buyer's logistics coordinator at each destination.

The logistics scheduling phase introduces further delays. When a factory books freight for a single-destination order, the process is straightforward: the entire shipment is palletized, a single freight booking is made, and the goods are collected by the carrier on a specified date. When the same order must be shipped to three locations, the factory must coordinate three separate freight bookings, which may involve three different carriers (if the buyer has preferred carriers for each region), three different collection dates (if the carriers have different pickup schedules), and three different delivery windows (if the buyer has specified different delivery deadlines for each location). In practice, this means the factory cannot release any of the three shipments until all three are ready to ship, because releasing the Auckland shipment early while the Wellington and Christchurch shipments are still being packed creates a situation where the buyer receives partial delivery and begins using the goods before the factory has confirmed that all three batches meet quality standards. If a defect is discovered in the Wellington batch after the Auckland batch has already been delivered and distributed to employees, the factory loses the ability to negotiate a consolidated remedy (such as a discount on the entire order or a replacement shipment for all three locations). Instead, the factory must manage three separate quality disputes, each with different stakeholders and different expectations.

The financial implications of multi-location delivery are rarely transparent to the buyer at the time the delivery instruction is given. Freight forwarders typically quote shipping costs on a per-shipment basis, not a per-unit basis. A single 10,000-unit shipment to Auckland might cost $1,200 in freight charges, resulting in a per-unit freight cost of $0.12. However, splitting the same order into three shipments—2,000 units to Auckland, 3,000 to Wellington, and 5,000 to Christchurch—might result in total freight charges of $2,400 ($600 for Auckland, $800 for Wellington, and $1,000 for Christchurch), because each shipment incurs a minimum freight charge regardless of volume. The per-unit freight cost increases to $0.24, effectively doubling the logistics expense. Buyers often discover this cost increase only after the factory has provided a revised quotation that includes the multi-location delivery surcharge, at which point the buyer must either accept the higher cost or consolidate the delivery to a single location and arrange internal distribution themselves. This decision-making process adds further delays, because it requires the buyer to obtain internal approval for the increased logistics budget or to coordinate with their own logistics team to determine whether consolidating delivery to a single warehouse and arranging secondary distribution is more cost-effective.

The root cause of this lead time extension is the disconnect between how procurement teams conceptualize orders and how factories operationalize fulfillment. From the buyer's perspective, a purchase order is a single transaction: the buyer specifies the product, the quantity, and the delivery locations, and the supplier is expected to fulfill the order as specified. From the factory's perspective, each delivery location represents a separate fulfillment project, because each location introduces independent variables—different consignees, different delivery windows, different quality control requirements, and different logistics coordination needs. The factory cannot treat a three-location order as a single production run with a simple shipping split, because doing so would expose the factory to quality disputes, logistics failures, and documentation errors that could result in payment delays or contract penalties. Instead, the factory must treat each location as a separate project, which requires additional time for coordination, verification, and scheduling.

The practical consequence for buyers is that requesting multi-location delivery after the production timeline has been agreed upon introduces a lead time extension that was not accounted for in the original schedule. If the buyer communicated the multi-location delivery requirement at the time of order placement, the factory could have built the additional coordination time into the production schedule. However, when the delivery instruction is provided late in the production cycle—often during the final quality control phase, when the buyer's logistics team finalizes the distribution plan—the factory must either delay shipment to accommodate the additional coordination work or ship the goods to a single location and allow the buyer to manage secondary distribution. Neither option is ideal: delaying shipment pushes back the buyer's delivery deadline, while consolidating delivery to a single location transfers the logistics complexity to the buyer's internal team, which may not have the resources or expertise to manage multi-location distribution efficiently.

For buyers who require multi-location delivery, the most effective strategy is to communicate this requirement at the time of order placement, not during the final stages of production. Early communication allows the factory to allocate additional time for quality control verification, packing list generation, and logistics coordination, and it allows the buyer to obtain accurate freight quotations that reflect the true cost of multi-location delivery. Buyers should also consider whether the benefits of direct delivery to multiple locations outweigh the costs and lead time extensions. In some cases, consolidating delivery to a single central warehouse and arranging secondary distribution through a domestic logistics provider may be more cost-effective and faster than requesting the factory to manage multi-location delivery. Domestic logistics providers typically have more flexible scheduling, lower minimum freight charges, and better knowledge of local delivery constraints, which can offset the additional handling required for secondary distribution.

The broader lesson is that lead time is not solely determined by production capacity or material availability. Lead time is also shaped by the complexity of the fulfillment requirements, and multi-location delivery is one of the most common sources of hidden complexity. Buyers who assume that specifying multiple delivery addresses is a simple shipping instruction often discover that this decision transforms a straightforward production timeline into a multi-phase coordination project that extends delivery by one to two weeks. Factories that fail to communicate this complexity to buyers early in the order process often find themselves managing rushed logistics coordination, quality disputes, and payment delays that could have been avoided with clearer expectations. The solution is not to avoid multi-location delivery entirely, but to recognize that it is a fulfillment complexity that requires additional lead time, and to plan accordingly from the outset.

Understanding [how production timelines are structured](/blog/custom-drinkware-production-lead-time-new-zealand) helps buyers recognize that delivery instructions are not merely shipping details—they are fulfillment specifications that directly affect how the factory schedules quality control, packing, and logistics coordination. When buyers treat delivery locations as variables that can be adjusted late in the production cycle, they inadvertently introduce coordination delays that extend lead times beyond the original schedule. The most reliable way to avoid these delays is to finalize delivery locations at the time of order placement, allowing the factory to build the necessary coordination time into the production timeline from the beginning.