2026-01-07 Production Process

Why Peak Season Orders Arrive Later Than Non-Peak Orders Despite Earlier Placement in Custom Drinkware

Overview

Buyers assume placing custom drinkware orders in September guarantees November delivery, but factory capacity constraints during peak season mean order placement date matters less than specification readiness and payment status.

Most procurement teams operate under the assumption that placing custom drinkware orders earlier in the calendar year—typically September or early October—secures priority positioning for November or December delivery. The logic appears straightforward: factories process orders sequentially, so earlier submissions should naturally translate to earlier completion dates. In practice, this timing strategy often backfires in ways that buyers don't anticipate until their expected delivery windows have already passed. The core issue isn't the placement date itself, but rather how factories allocate production capacity when operating under peak season constraints.

Factories manufacturing custom drinkware face a predictable annual pattern where Q3 order intake surges as corporate buyers prepare for year-end gifting programmes, holiday campaigns, and Q1 product launches. This surge creates what appears to be a straightforward capacity management problem: more orders arrive than the factory can immediately process, so orders queue up and wait their turn. Buyers who understand this dynamic attempt to "get ahead" by submitting orders in September, believing this early placement guarantees they'll reach the front of the queue before the October and November rush intensifies.

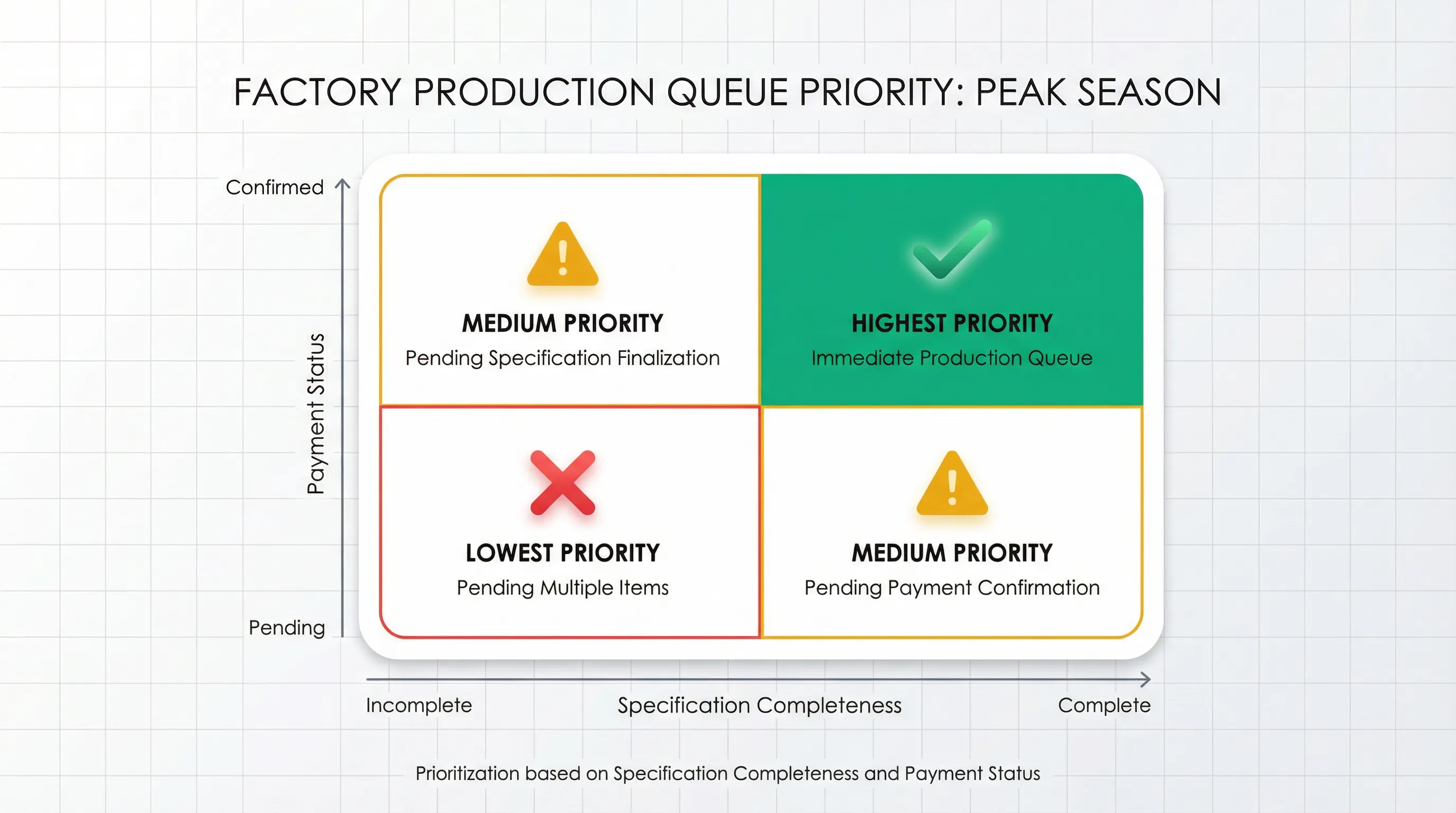

What buyers fail to recognize is that factories don't process orders based purely on submission date. Instead, they prioritize orders based on production readiness—a composite assessment that considers specification completeness, artwork approval status, payment confirmation, and material availability. An order submitted in September that lacks finalized artwork or confirmed payment sits in a "pending" queue that's separate from the active production schedule. Meanwhile, an order submitted in October with complete specifications, approved artwork, and confirmed payment moves directly into the production queue and begins manufacturing within days.

This prioritization logic stems from how factories manage capacity constraints during peak periods. When production lines operate near maximum capacity, factories cannot afford to hold slots open for orders that might require specification changes, artwork revisions, or payment confirmation delays. Each production slot represents a fixed window of machine time, labor allocation, and material staging. If an order isn't ready to proceed through all manufacturing stages without interruption, the factory reallocates that slot to an order that is ready, regardless of which order was submitted first.

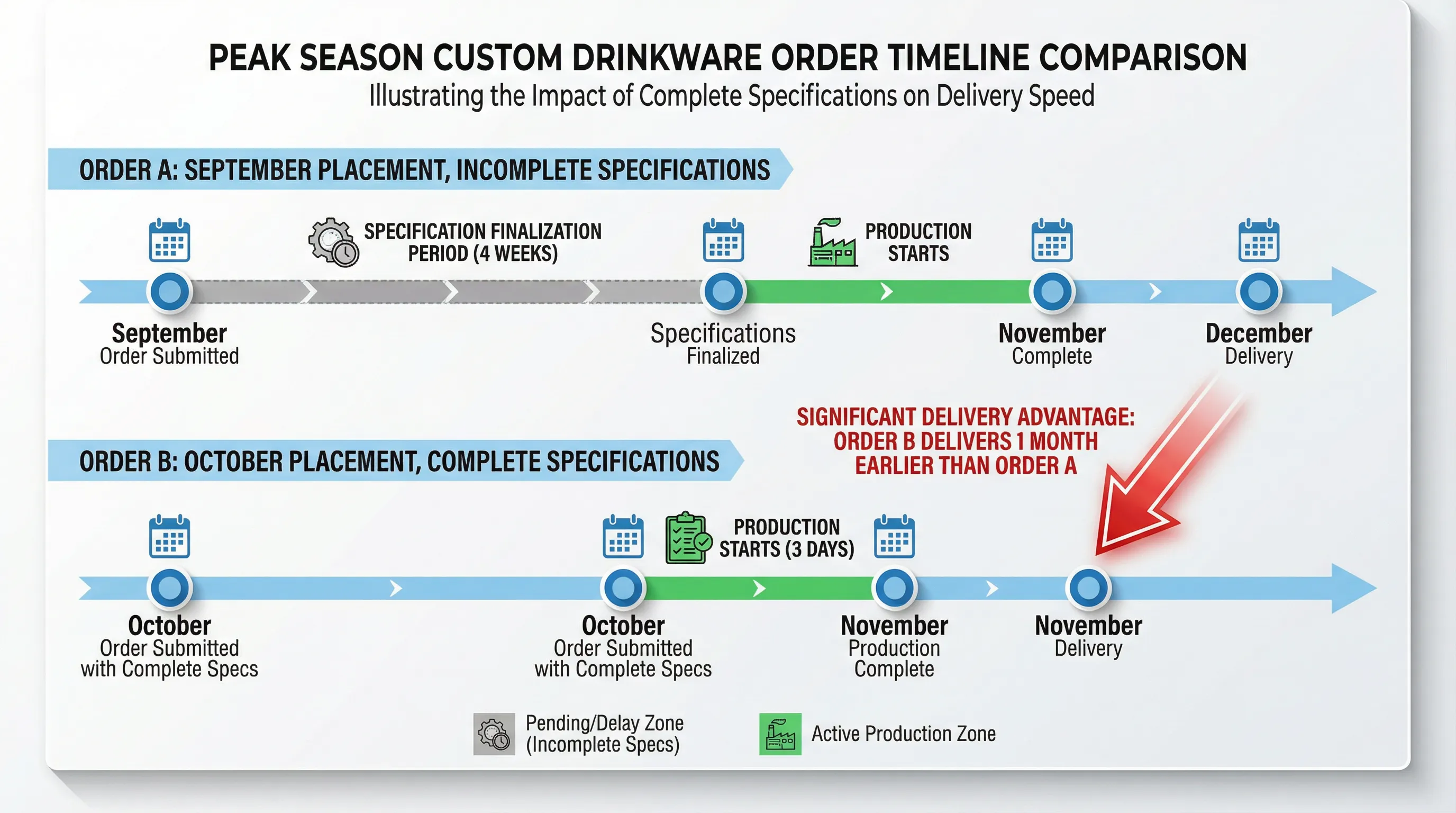

The practical consequence is that buyers who submit "placeholder" orders in September—intending to finalize details later—often discover their orders don't enter actual production until November, by which time their intended delivery window has closed. A buyer who submits a fully specified order in October, by contrast, may see their goods complete production by early November, despite placing the order a full month later than the September buyer.

This dynamic creates a counterintuitive outcome where [overall production timelines](/blog/custom-drinkware-production-lead-time-nz-businesses) for peak season orders depend more heavily on specification readiness than on order placement date. Factories operating under capacity constraints prioritize throughput efficiency over chronological fairness. An order that can move through production without delays or interruptions generates more value for the factory than an order that requires multiple rounds of clarification, artwork revision, or payment follow-up, even if the latter was submitted earlier.

The capacity constraint framework helps explain why this prioritization pattern emerges. During non-peak periods, factories have sufficient slack capacity to accommodate specification changes, artwork revisions, and payment delays without disrupting overall production schedules. An order submitted with incomplete specifications in March might sit in pending status for two weeks while the buyer finalizes details, and the factory simply allocates that production slot to another order in the meantime. When the March order becomes ready, the factory has available capacity to slot it into the schedule without causing delays to other orders.

During peak season, however, slack capacity disappears. Every production slot is spoken for, and the queue of ready-to-produce orders exceeds available capacity. In this environment, an order that sits in pending status doesn't just wait for an open slot—it actively loses its position in the queue as other orders with complete specifications move ahead. The factory cannot afford to reserve capacity for orders that might become ready at some undefined future date, because doing so would leave production lines idle while ready-to-produce orders wait unnecessarily.

Buyers who understand this dynamic recognize that peak season ordering requires a fundamentally different approach than non-peak ordering. The goal isn't to submit orders early and finalize details later; the goal is to finalize all details before submission, ensuring the order enters the production queue immediately rather than sitting in pending status. This means completing artwork approval, confirming payment, and locking down all specification details before the order reaches the factory, rather than treating these steps as post-submission activities.

The challenge is that many procurement workflows aren't designed to support this front-loaded preparation. Buyers often submit orders based on preliminary specifications, expecting to refine details through the proof approval process. This approach works well during non-peak periods when factories have capacity to accommodate iterative refinement. During peak season, however, this workflow pattern creates exactly the kind of specification uncertainty that causes orders to lose priority positioning.

Some buyers attempt to game this system by submitting orders with "placeholder" specifications in September, intending to update details once internal stakeholders finalize requirements. The assumption is that having an order "in the system" preserves their early submission date, even if specifications aren't final. Factories, however, don't honor this approach. An order with placeholder specifications doesn't enter the production queue until all placeholders are replaced with final specifications, at which point the order's effective submission date becomes the date when specifications were finalized, not the date when the placeholder order was initially submitted.

This creates a scenario where a buyer who submits a placeholder order in September and finalizes specifications in October effectively has an October submission date from the factory's perspective. If another buyer submits a fully specified order in late September, that buyer's order will enter production ahead of the placeholder order, even though both orders were technically "submitted" in September. The factory treats specification finalization as the true submission date for production scheduling purposes, regardless of when the initial order form was received.

The payment confirmation dimension adds another layer of complexity. Factories operating under peak season capacity constraints prioritize orders with confirmed payment over orders with pending payment, even if the pending-payment orders were submitted earlier. This prioritization reflects the factory's risk management approach: an order without confirmed payment carries execution risk that the factory cannot afford during peak periods when production slots are at a premium. If a buyer submits an order in September but payment confirmation doesn't arrive until October, the factory treats that order as an October order for scheduling purposes, and any orders with confirmed payment submitted in late September will move ahead in the queue.

Buyers who recognize these prioritization patterns adjust their peak season ordering strategies accordingly. Instead of rushing to submit orders early with incomplete specifications, they invest time in finalizing all details before submission. This might mean delaying submission from early September to late September, but the trade-off is worthwhile: a late September order with complete specifications enters production immediately, while an early September order with incomplete specifications sits in pending status until October.

The broader implication is that peak season lead time management requires buyers to shift their focus from order placement timing to specification readiness timing. The question isn't "when should I submit my order to ensure November delivery?" but rather "when do I need to have all specifications finalized to ensure my order enters production in time for November delivery?" The answer to the second question typically requires working backward from the desired delivery date, accounting for production time, shipping time, and the factory's current queue depth for ready-to-produce orders.

Factories rarely communicate this prioritization logic explicitly to buyers, because doing so would require explaining that submission date doesn't guarantee queue position—a message that could create confusion or dissatisfaction among buyers who assume chronological processing. Instead, factories simply process orders based on production readiness and allow buyers to draw their own conclusions from observed lead times. Buyers who submit early but finalize late experience longer lead times than buyers who submit late but finalize early, and over time, experienced buyers learn to prioritize specification readiness over submission timing.

The practical takeaway is that peak season ordering demands a front-loaded preparation approach that differs fundamentally from non-peak ordering patterns. Buyers cannot rely on early submission dates to secure priority positioning unless those submissions include complete specifications, approved artwork, and confirmed payment. Orders that lack any of these elements will lose queue position to later-submitted orders that have all elements in place, regardless of the initial submission date. Understanding this dynamic allows buyers to structure their internal approval workflows to support specification finalization before submission, rather than treating submission as the starting point for specification refinement.