Why Waiting for Final Inspection to Verify Custom Drinkware Quality Costs More Than Earlier Checkpoints

Overview

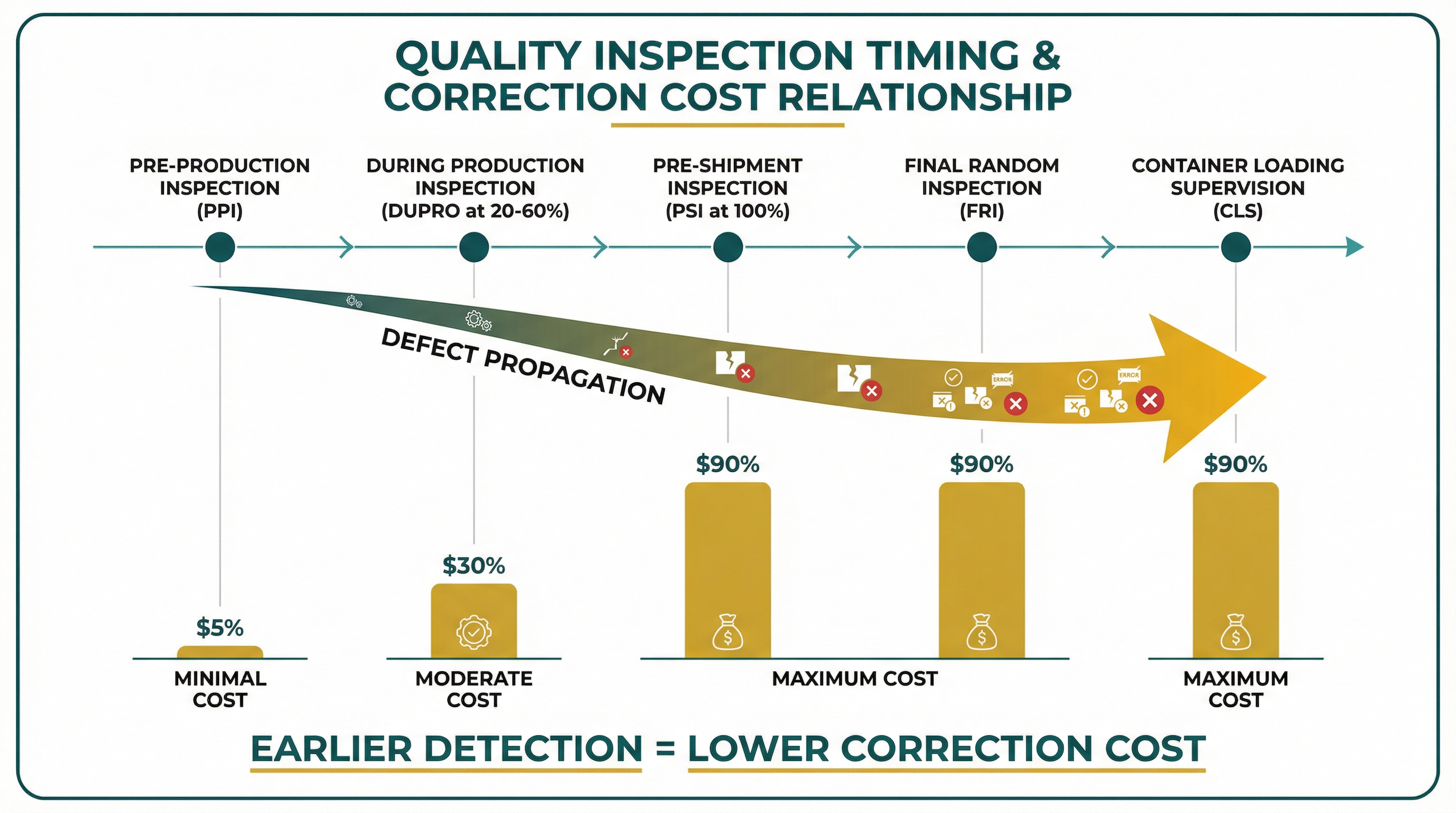

Most buyers request quality inspection only when production is complete. By that point, defects have already propagated through the entire order, making corrections expensive and time-consuming.

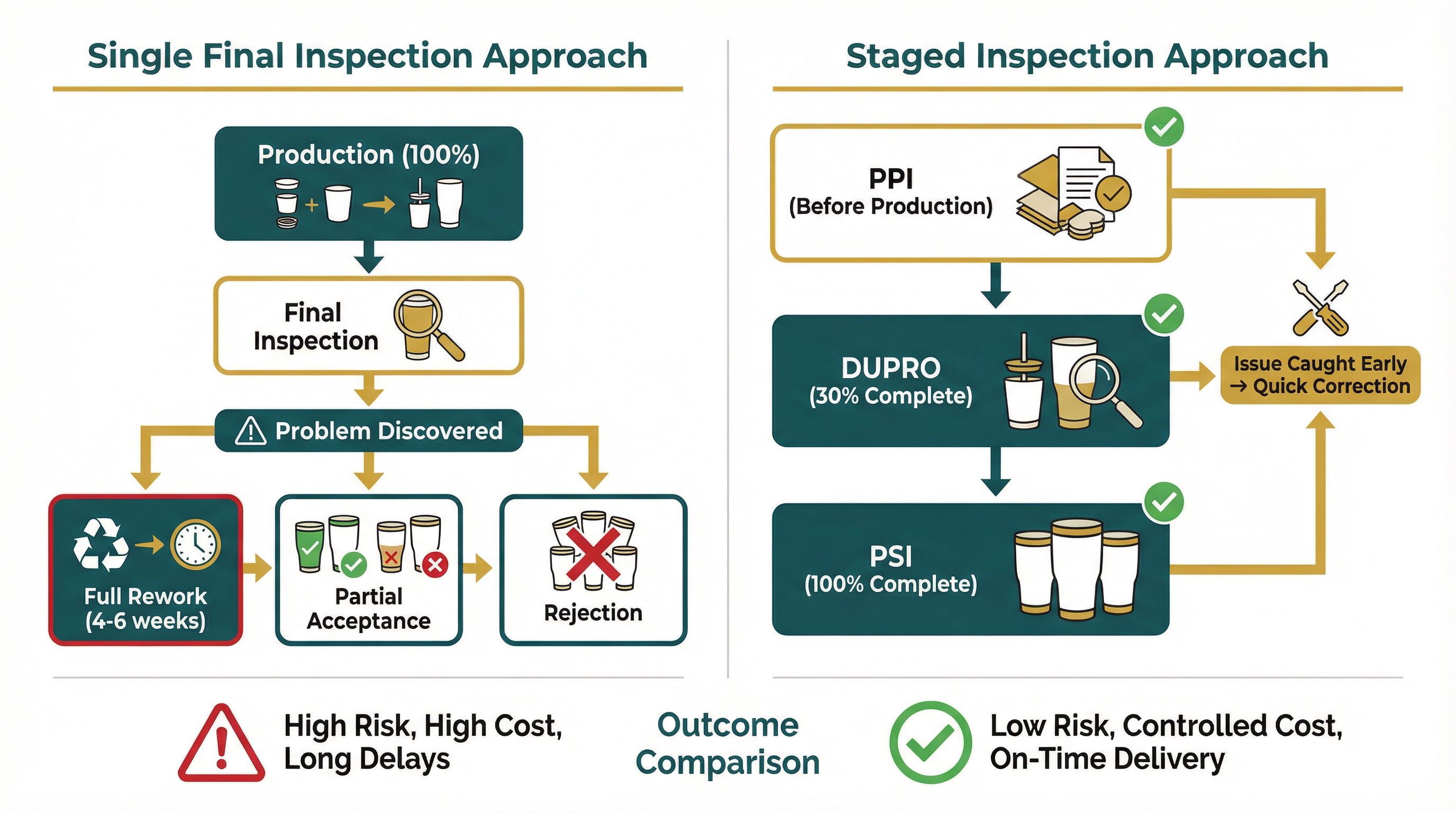

There is a pattern we observe repeatedly in custom drinkware manufacturing: buyers request quality inspection at the end of production, receive a report identifying defects, and then face a difficult decision about whether to accept compromised quality, negotiate partial refunds, or wait for rework that extends the timeline by weeks. The frustration in these situations is understandable, but the root cause is rarely discussed. The timing of quality verification—not the verification itself—determines whether defects can be corrected efficiently or whether they become embedded problems that require expensive remediation.

From a production floor perspective, the customization process for corporate drinkware involves multiple stages where quality can deviate from specifications. Raw materials arrive with varying consistency. Coating application depends on environmental conditions and equipment calibration. Logo imprinting requires precise alignment and pressure settings that may drift over a production run. Packaging assembly introduces opportunities for damage or mislabeling. Each of these stages represents a potential point of failure, and each has a different cost profile for correction depending on when the issue is identified.

The fundamental economics of quality inspection timing are straightforward but rarely communicated to buyers. Identifying a raw material defect before production begins costs almost nothing to correct—the supplier replaces the defective batch, and production proceeds on schedule. Identifying the same defect during production, when twenty percent of the order has been completed, requires discarding or reworking the affected units, but the remaining eighty percent can be manufactured correctly. Identifying the defect only at final inspection, when the entire order is complete and packed, means every unit is potentially affected, and the correction options are limited to full rework, partial acceptance, or rejection.

In practice, this is where customization process decisions begin to be misjudged. Buyers assume that requesting a "quality inspection" at the end of production is sufficient to ensure they receive acceptable products. What they do not realize is that final inspection is a verification checkpoint, not a correction opportunity. By the time final inspection occurs, the production window has closed. The equipment has been reconfigured for the next order. The workers have moved to different tasks. Correcting defects at this stage requires reopening the production line, which introduces setup costs, scheduling delays, and the risk of inconsistency between the original and corrected batches.

The cost differential between inspection stages is substantial. A pre-production inspection that identifies substandard raw materials might delay the project by a few days while replacement materials are sourced. A during-production inspection that catches coating inconsistency at the thirty percent mark might require discarding a few hundred units and adjusting the equipment settings. A final inspection that reveals the same coating inconsistency across the entire order requires either accepting products that do not meet specifications, negotiating a price reduction that may not compensate for the quality compromise, or waiting four to six weeks for a complete remanufacture.

The challenge for buyers is that inspection services are typically priced per visit, creating an incentive to minimize the number of inspections. A single final inspection appears more cost-effective than multiple inspections at different production stages. This calculation ignores the risk-adjusted cost of defects. If final inspection reveals a problem, the cost of correction far exceeds the savings from skipping earlier checkpoints. If earlier inspections would have caught the problem when correction was cheap, the apparent savings from a single-inspection approach become an expensive false economy.

For organisations managing custom drinkware projects, the practical guidance is to align inspection timing with the production stages where quality risks are highest. For orders involving custom powder coating or color matching, a during-production inspection when twenty to thirty percent of units are complete provides an opportunity to verify color consistency before the majority of the order is manufactured. For orders involving logo imprinting, inspecting the first production batch before full-scale manufacturing begins confirms that alignment, pressure, and ink adhesion meet specifications. For orders with complex packaging requirements, verifying packaging quality before container loading prevents damage during transit.

The inspection timing decision is not about adding cost—it is about allocating quality verification resources to the stages where they provide the most value. A buyer who spends the same total budget on two strategically timed inspections rather than one final inspection will consistently achieve better outcomes than a buyer who concentrates all verification at the end. The former catches problems when they can be corrected efficiently. The latter discovers problems when correction options are limited and expensive.

Understanding how inspection timing affects correction costs is a critical component of managing the complete customization workflow for corporate drinkware. Buyers who treat quality inspection as a single end-of-process event consistently encounter situations where defects are discovered too late for efficient correction. Those who understand the relationship between inspection timing and correction economics build verification checkpoints into their project timelines at the stages where quality risks are highest, and they avoid the frustration of receiving final inspection reports that identify problems with no practical solution.

The gap between inspection timing and correction opportunity is not a failure of inspection quality. It is a consequence of treating quality verification as a single event rather than a staged process. Organisations that understand this distinction approach inspection planning with appropriate strategic consideration and avoid the costly discovery that their custom drinkware order has defects that could have been corrected weeks earlier at a fraction of the cost.