Why Reordering Custom Bottles Creates Colour Matching Challenges

Overview

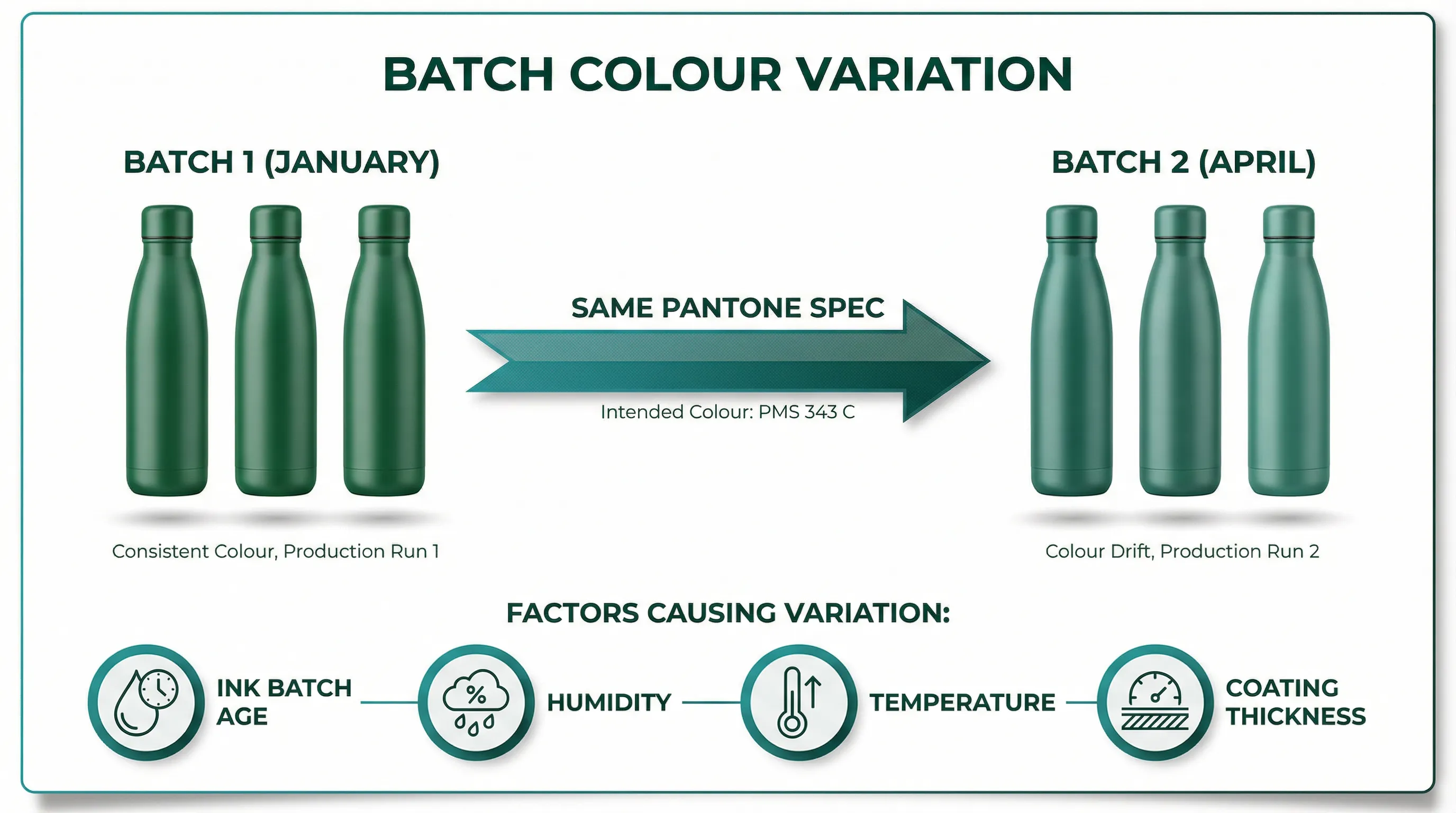

The hidden risk of splitting drinkware orders across time—and why your second batch of branded stainless steel bottles may not match the first.

The decision to order custom stainless steel bottles or branded ceramic mugs at the minimum quantity often follows a reasonable logic: test the product with a small group, evaluate the response, and scale up with a larger order if the feedback is positive. What this approach fails to account for is the colour consistency challenge that emerges when the reorder arrives three months later and the Pantone 3435 C on the new batch no longer matches the Pantone 3435 C on the original.

This is not a quality control failure in the traditional sense. The supplier has done nothing wrong. Both batches were produced to the same specification, using the same Pantone reference, on the same equipment. The variation exists because manufacturing processes—particularly those involving powder coating on stainless steel, glaze application on ceramics, or screen printing on glass—are subject to variables that shift between production runs. Ink batches age. Powder coating formulations are remixed. Kiln temperatures fluctuate by fractions of a degree that are imperceptible to operators but visible on the finished product. The result is a colour drift that falls within acceptable tolerance ranges but creates visible inconsistency when the two batches sit side by side.

The Brand Consistency Problem

For organisations using branded drinkware as part of employee onboarding or client gifting programmes, this inconsistency creates problems that extend beyond aesthetics. A new hire receiving a water bottle in January and another receiving the same bottle in July may notice that the corporate green looks different. Neither bottle is defective, but the perception of inconsistency undermines the brand cohesion the merchandise was meant to reinforce. In client-facing contexts, the issue is more acute—a gift set assembled from two different production runs may contain items that visibly do not match.

Why Pantone Matching Is Not Enough

The underlying issue is that Pantone matching, while essential, is a specification rather than a guarantee. A Pantone reference tells the manufacturer what colour to target, but it does not control the variables that determine whether two production runs will produce identical results. Powder coating on insulated travel mugs, for instance, involves electrostatic application followed by heat curing. The thickness of the coating, the ambient humidity during application, and the exact temperature profile of the curing oven all influence the final colour. A supplier running the same Pantone specification on two different days may produce results that both fall within the acceptable delta E tolerance but differ enough to be noticeable when compared directly.

Implications for Order Quantity Decisions

The practical implication for procurement decisions is that splitting orders across time—ordering at the minimum now and reordering later—introduces a risk that ordering in a single larger batch would avoid. This does not mean every organisation should automatically order above their immediate needs, but it does mean the decision to order at minimum should factor in the likelihood of reordering and the importance of colour consistency to the programme's objectives. Understanding how order quantities affect long-term brand consistency provides a more complete picture of what these decisions actually entail.

Mitigation Strategies

For programmes where brand consistency is critical, there are mitigation strategies worth considering. Some suppliers offer batch retention services, holding back a portion of the original ink or coating formulation for future orders. Others can produce a larger initial run and warehouse the excess for staged delivery. These arrangements typically carry additional costs, but they may be justified when the alternative is visible inconsistency across a branded drinkware programme that spans multiple quarters or employee cohorts.

The colour consistency challenge is one of several factors that influence how organisations approach their initial order quantities for custom bottles, mugs, and tumblers. Understanding the relationship between batch timing and colour variation provides a more complete picture of what minimum quantity decisions actually entail—and why the lowest number on the quote sheet is not always the most cost-effective choice over the life of a merchandise programme.