2026-01-06 Production Process

Why Shipping Method Indecision Extends Custom Drinkware Production Timelines

Overview

Procurement teams often delay sea freight vs air freight decisions until production completes, not realizing this choice affects packing specifications and adds hidden weeks to custom drinkware lead times.

Most procurement teams treat the sea freight versus air freight decision as something to finalize once production wraps up. The logic seems sound: wait until the goods are ready, then choose the most cost-effective shipping method based on current rates and delivery urgency. In practice, this delayed decision-making creates a hidden extension to [overall production timelines](/blog/custom-drinkware-production-lead-time-nz-businesses) that buyers rarely anticipate until it's too late.

The issue stems from a fundamental misunderstanding of how shipping method choice affects production planning. Buyers assume that packing happens uniformly regardless of whether goods will travel by sea or air, but factory-side reality tells a different story. Air freight and sea freight require fundamentally different packing specifications, and factories cannot finalize packing protocols until the buyer commits to a shipping method.

Air freight packing prioritizes dimensional weight optimization. Airlines calculate chargeable weight using both actual weight and volumetric weight—whichever is higher. The formula (length × width × height in centimeters ÷ 6,000) means that even lightweight custom drinkware can incur substantial costs if packed inefficiently. Factories must design carton dimensions to minimize wasted space, often requiring custom carton sizes or specific product arrangements that differ from standard packing configurations. This optimization process takes time and cannot begin until the buyer confirms air freight as the chosen method.

Sea freight packing follows entirely different priorities. Ocean carriers charge based on cubic meters for less-than-container-load shipments, making carton consolidation more important than individual carton dimensions. Factories can use heavier, moisture-resistant packing materials without worrying about weight penalties. The packing density can be lower because volumetric efficiency matters more than dimensional weight calculations. Additionally, sea freight requires moisture barriers and desiccants that air freight shipments typically skip, adding another layer of specification that must be confirmed before final packing begins.

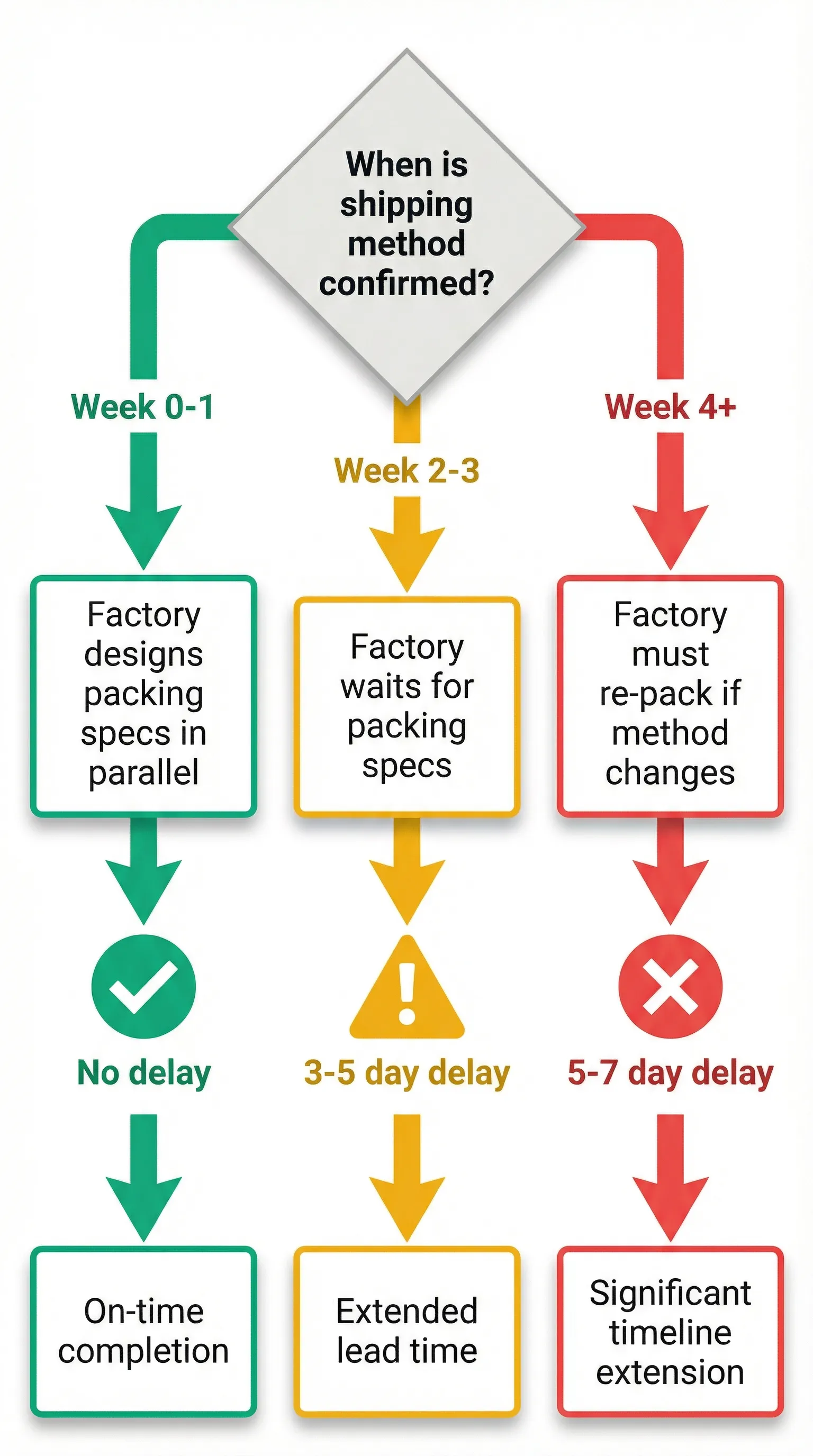

When buyers delay the shipping method decision beyond week two of a typical 35-day production cycle, factories face a packing specification bottleneck. Production lines complete manufacturing on schedule, but finished goods sit in holding areas waiting for packing instructions. The factory cannot risk packing for sea freight if the buyer might switch to air freight at the last minute, because re-packing would require unpacking, re-arranging products, sourcing different carton sizes, and re-labeling—a process that can consume five to seven additional days.

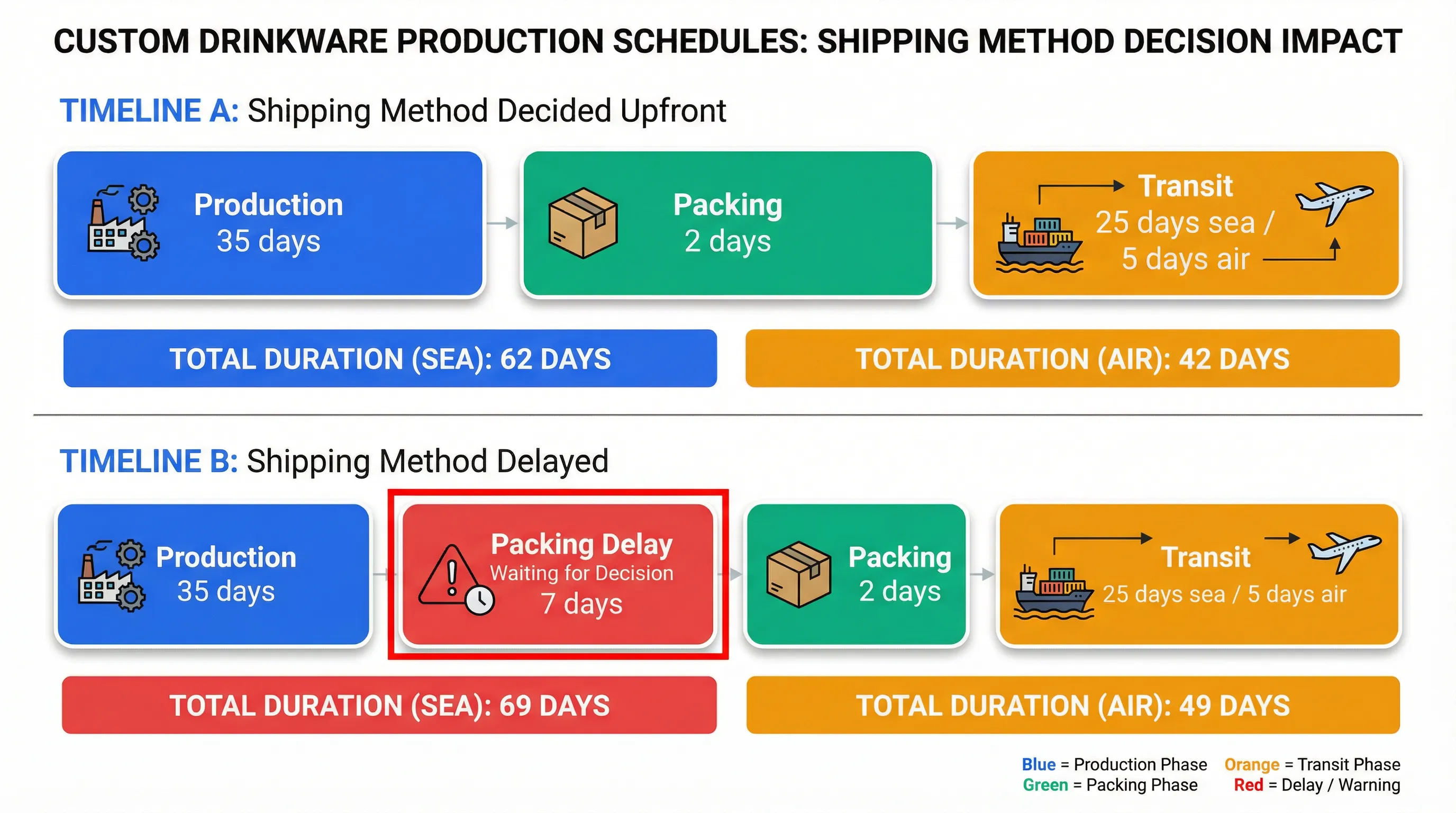

This waiting period extends the total lead time in ways that buyers don't capture in their initial timeline calculations. A buyer who estimates 35 days production plus 25 days sea freight (total 60 days) might discover the actual timeline is 35 days production plus 7 days packing delay plus 25 days transit, reaching 67 days. If the buyer then panics about the delay and switches to air freight during week four, the factory must scramble to re-optimize packing for dimensional weight, often adding another three to five days before goods can actually ship.

The problem compounds when buyers use shipping method flexibility as a hedge against uncertainty. Some procurement teams intentionally avoid committing to a shipping method early, believing this preserves optionality if market conditions change or if production delays occur. What they fail to recognize is that this "flexibility" transfers scheduling risk directly onto the factory floor, where it manifests as packing delays that ultimately extend the buyer's own lead time.

Factories prioritize orders with confirmed shipping methods because these orders have clear packing specifications and can move through final stages without interruption. Orders without shipping method confirmation sit in a lower priority queue, waiting for buyer decisions before packing resources can be allocated. During peak production periods, this priority difference can stretch packing delays from days into weeks, as factories allocate limited packing line capacity to orders with complete specifications first.

The solution requires buyers to treat shipping method selection as a production planning decision rather than a post-production logistics choice. Committing to a shipping method during the order confirmation phase—ideally before production begins—allows factories to design packing protocols in parallel with manufacturing. This upfront decision doesn't eliminate the ability to change shipping methods if circumstances shift, but it establishes a baseline packing specification that minimizes delays if the original plan holds.

For orders where genuine uncertainty exists about shipping method requirements, buyers should specify a "default packing mode" that the factory can use unless explicitly instructed otherwise. Most factories recommend defaulting to sea freight packing specifications, as these are generally more robust and can accommodate air freight with minimal adjustment if needed. The reverse—defaulting to air freight packing and then switching to sea freight—often requires more extensive re-packing because air-optimized cartons may lack the moisture protection and structural reinforcement that ocean transit demands.

The broader lesson is that lead time management extends beyond tracking production days and transit days. Hidden delays accumulate in the transition phases between manufacturing and shipping, and these transition delays often trace back to decision-making patterns that buyers control. Shipping method indecision represents one of the most common yet preventable sources of timeline extension in custom drinkware orders, and addressing it requires recognizing that logistics decisions have upstream effects on production scheduling that manifest long before goods leave the factory floor.