Why Buyer Procurement Decision Delays Extend Custom Drinkware Lead Times by 2-4 Weeks

Overview

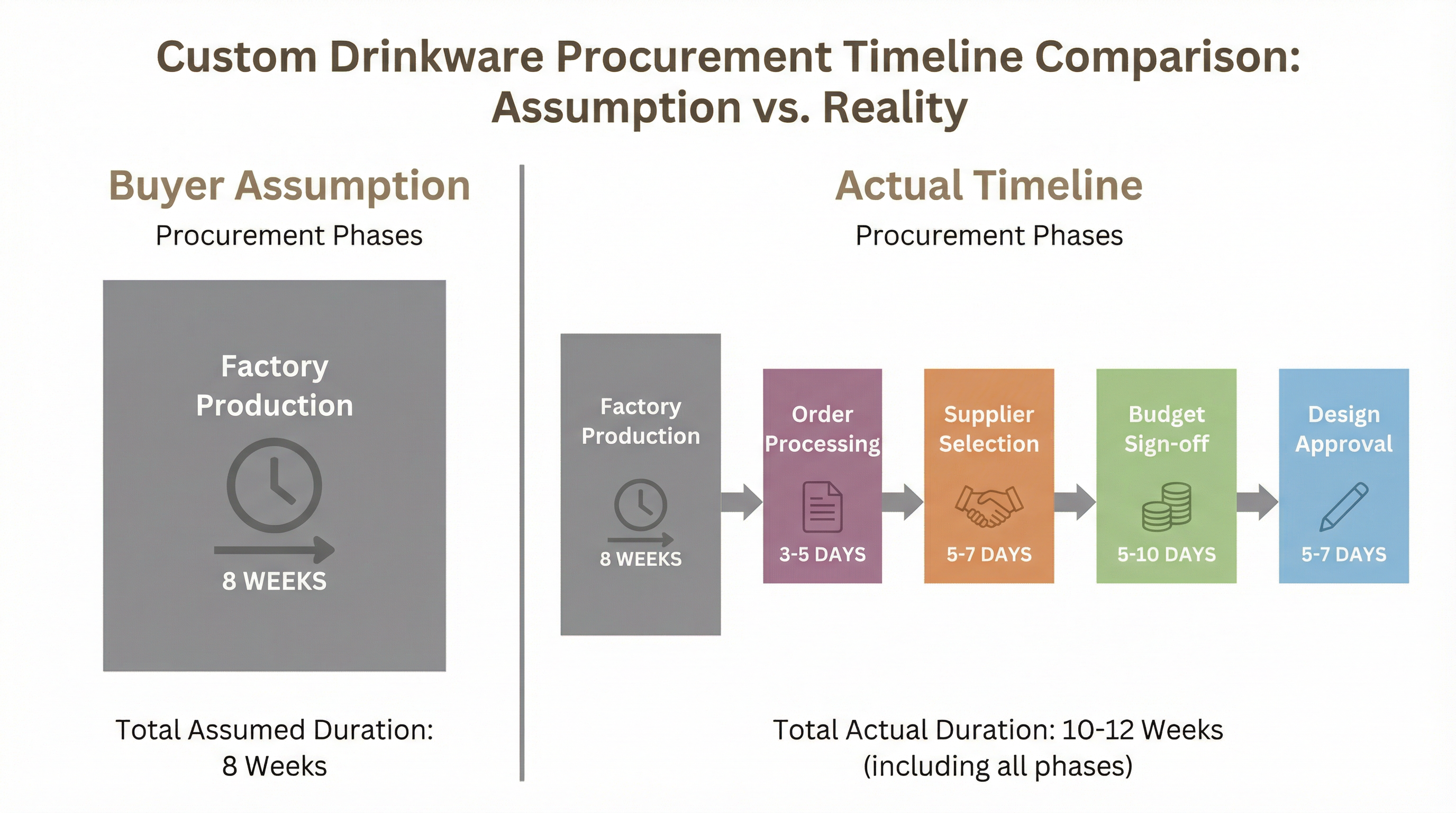

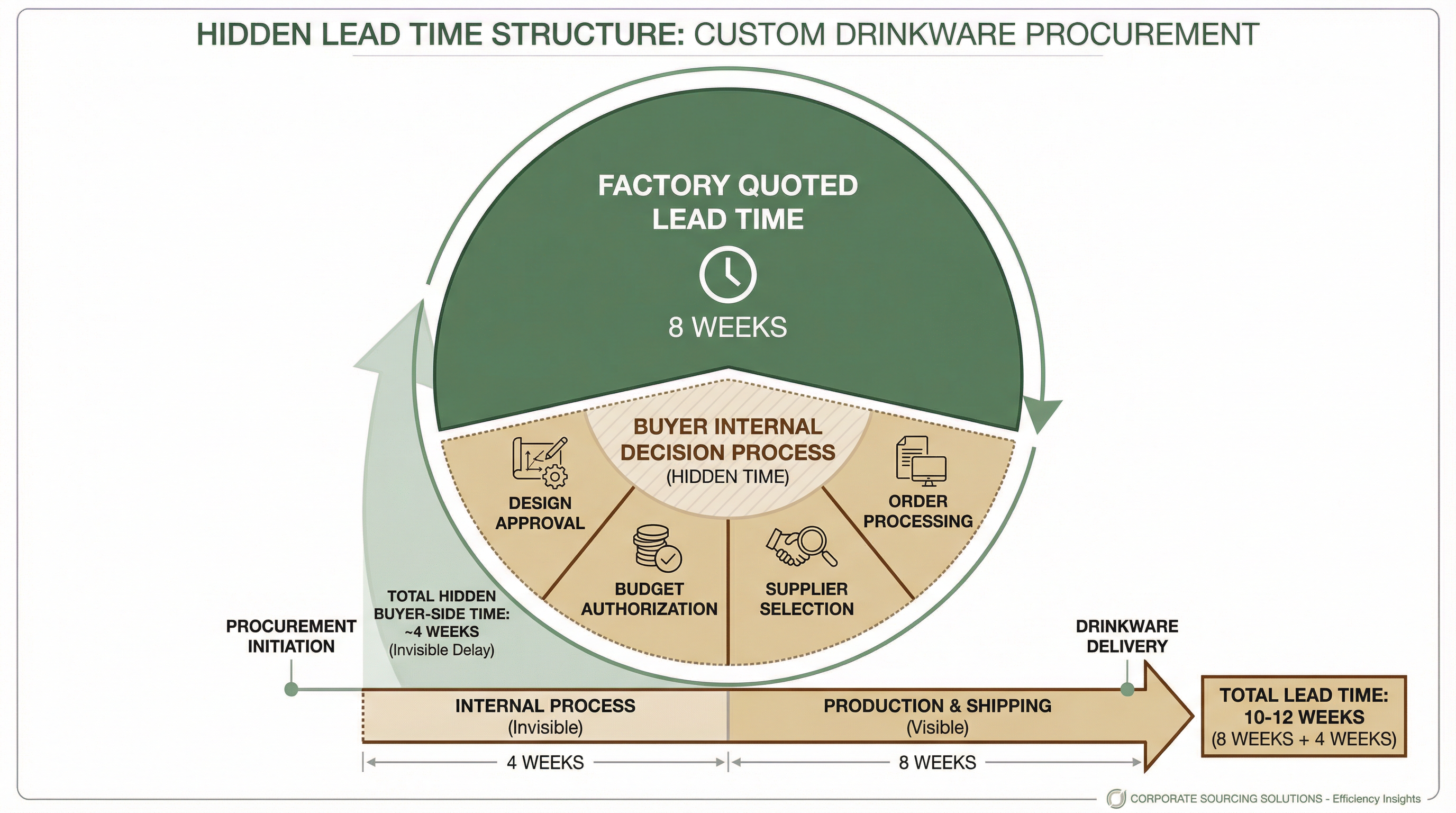

When procurement managers receive a factory quote stating '8-week lead time,' they often overlook that their own internal decision processes (design approval, budget sign-off, supplier selection, order processing) consume 2-4 weeks before the factory even begins production. This 'invisible lead time' causes organisations to believe they have 8 weeks of buffer when they actually only have 4-6 weeks.

When procurement managers request quotes from factories, the typical response is "8-week lead time." This figure appears clear and straightforward, yet it conceals a critical blind spot: the factory's quoted 8-week lead time begins from the moment they receive the official purchase order, not from when the buyer first starts considering the order. This perception gap causes many organisations planning promotional gifts or employee benefits to mistakenly believe they have 8 weeks of buffer time, only to discover on the eve of their event that goods have not yet shipped, leaving them in a reactive position.

The root of the problem lies in buyers treating "factory production time" as the only lead time variable while ignoring that their own internal decision processes consume equally significant time. Between initial enquiry and formal order placement, organisations must navigate design approval, budget authorisation, supplier selection, and contract negotiation—each requiring coordination and confirmation across different departments. These processes may appear independent, but they actually form a sequential decision chain where any delay directly postpones the purchase order issuance, thereby compressing the factory's actual production window.

The design approval process is the first commonly underestimated time sink. When an organisation decides to order custom drinkware as branded promotional items, the marketing department typically needs to confirm logo size, position, colour, and whether additional slogans or graphics are required. This process appears simple but actually involves integrating opinions from multiple stakeholders. Marketing managers may want the logo more prominent, brand managers may worry about designs appearing too obtrusive and affecting brand image, while finance departments focus on whether printing costs will increase due to design complexity. These discussions often require several meetings to reach consensus, with intervals between meetings further extended by participants' scheduling conflicts. Even after the final design receives internal approval, it must be submitted to the factory for technical feasibility assessment to confirm whether printing processes can achieve the expected results. This entire process typically requires 5 to 7 working days, and this time occurs entirely outside the factory's quoted "8-week lead time."

Budget authorisation procedures represent the second invisible time sink. Even after design approval is secured, procurement departments must still apply to finance for budget approval. In many organisations, purchases exceeding certain amounts require multi-level approval, from department heads to CFOs, sometimes requiring final sign-off from the CEO. The length of this approval process depends on organisational size and internal control systems. Small to medium enterprises may need only 3 to 5 days, but large corporations or multinational companies may have approval processes lasting 10 to 15 days. More challenging still, if procurement applications coincide with fiscal year-end closing, budget freezes, or senior executives travelling and unable to sign promptly, the entire process may be forced to pause until relevant personnel return to their positions. This waiting time likewise is not counted in the factory's production lead time, yet it genuinely extends the order's overall completion time.

Supplier selection and negotiation represents the third easily overlooked time cost. Even when organisations have suppliers they have worked with for years, procurement departments may still require multi-vendor comparison based on cost considerations or risk diversification principles. This means procurement staff must send enquiries to at least three factories, wait for each to respond with quotes and samples, then conduct comprehensive evaluation. This process requires not only time to collect information but also time for internal discussions comparing each supplier's price, quality, lead time, and after-sales service. If the organisation decides to switch suppliers, additional time is needed for supplier qualification review, factory site visits, and contract term negotiations. Even if the ultimately selected supplier is the original partner, this entire comparison and evaluation process still consumes 5 to 7 working days, and this time likewise occurs before the factory begins production.

Purchase order processing is the final underestimated time element. After all internal approvals are complete, procurement departments must formally issue purchase orders and confirm order details with suppliers, including product specifications, quantities, unit prices, lead times, payment terms, and shipping methods. This process appears to be mere administrative work but actually requires back-and-forth confirmation between both parties to ensure no misunderstandings or omissions. For larger order amounts, legal departments may need to review contract terms to protect the organisation's interests. This final confirmation and order issuance process typically requires 3 to 5 working days. Only when suppliers formally receive the purchase order and confirm acceptance does the factory's "8-week production lead time" truly begin counting.

These four stages combined typically consume 20 to 29 working days, equivalent to 4 to 6 weeks. This means when organisations believe they have 8 weeks to complete an order, the actual time remaining for factory production may be only 2 to 4 weeks. If organisations encounter design revisions, budget adjustments, or supplier changes during this period, the entire timeline becomes further compressed, ultimately causing orders to miss delivery deadlines.

The more serious problem is that buyers often fail to recognise how their own decision delays impact lead times. When orders ultimately deliver late, buyers typically attribute responsibility to factory production efficiency or logistics issues, overlooking that their own internal decision processes are the primary cause of extended lead times. This cognitive bias not only affects trust relationships between buyers and suppliers but also causes organisations to repeat the same mistakes in future procurement planning, falling into a vicious cycle of "never having enough time."

From the factory's perspective, buyer decision delays directly affect production scheduling stability. When quoting, factories typically estimate reasonable lead times based on current capacity status and order schedules. However, when buyers delay ordering due to internal process delays, the production slots factories originally reserved may already be occupied by other orders, requiring this order to be rescheduled into later production queues. In such situations, even if factories are willing to accommodate buyers' urgent needs, they may be unable to deliver early due to full capacity, ultimately having to extend lead times or add rush fees.

The key to solving this problem lies in buyers redefining the concept of "lead time." Lead time should not merely be the factory's quoted production time but should be the total time from "when the organisation begins planning procurement" to "when goods are actually delivered." This means when organisations plan promotional gifts or employee benefits, they must factor their internal decision process time into consideration, reserving sufficient buffer time to handle potential delays. If an event is planned for 12 weeks away and the factory's quoted lead time is 8 weeks, organisations should begin the procurement process 12 weeks before the event, not wait until 8 weeks before to start enquiring.

Another effective strategy is optimising internal decision processes to reduce unnecessary approval stages and waiting time. Organisations can establish standardised procurement processes that clearly define responsible parties and deadlines for each stage, avoiding delays caused by poor communication or unclear responsibilities. For example, design approval can set deadlines of "complete initial review within 3 working days, complete final confirmation within 5 working days," while budget authorisation can establish delegation mechanisms where "amounts within certain ranges are approved directly by department heads, with higher-level approval required only for amounts exceeding the threshold." These measures can effectively shorten internal decision time, allowing purchase orders to be issued more quickly and securing more adequate production time for factories.

Establishing long-term partnerships with suppliers in advance is also an important method for reducing decision delays. When stable trust relationships have been established between organisations and suppliers, many processes can be simplified or eliminated. For example, design approval can directly reference past successful cases, budget authorisation can be quickly estimated based on historical quotes, and supplier selection can skip comparison procedures and order directly. Such long-term partnerships not only shorten procurement cycles but also make suppliers more willing to accommodate buyers' urgent needs, providing more flexible production scheduling and lead time arrangements.

From a broader perspective, buyer decision delay problems reflect systemic deficiencies in organisational procurement management. Many organisations view procurement as purely transactional behaviour, overlooking that procurement itself is a complex process requiring cross-departmental collaboration, multi-level approval, and long-term planning. This cognitive bias causes organisations when formulating procurement plans to focus only on supplier quotes and lead times while ignoring how their own internal decision efficiency affects overall lead times. To truly solve this problem, organisations need systematic reform across organisational structure, process design, and performance evaluation, elevating procurement management to strategic level rather than merely execution-level administrative work.

Understanding the complete lead time structure for custom drinkware helps organisations more accurately estimate total time required when planning procurement, avoiding lead time delays caused by overlooking internal decision processes. When organisations can clearly recognise how their own decision delays affect lead times, they can truly master procurement rhythm, ensure orders deliver on schedule, and avoid falling into reactive situations.

Buyer procurement decision delays are the invisible driver of extended custom drinkware order lead times. Solving this problem requires not only organisations optimising internal processes but also establishing more transparent and collaborative communication mechanisms between buyers and suppliers, working together to shorten overall lead times. Only when buyers truly understand that "lead time" is not merely factory production time but total time including their own internal decision processes can they fundamentally avoid lead time delay risks and ensure procurement plans execute successfully.