Why Supplier Switching Extends Custom Drinkware Lead Times by 3-5 Weeks—Even When Product Specifications Are Identical

Overview

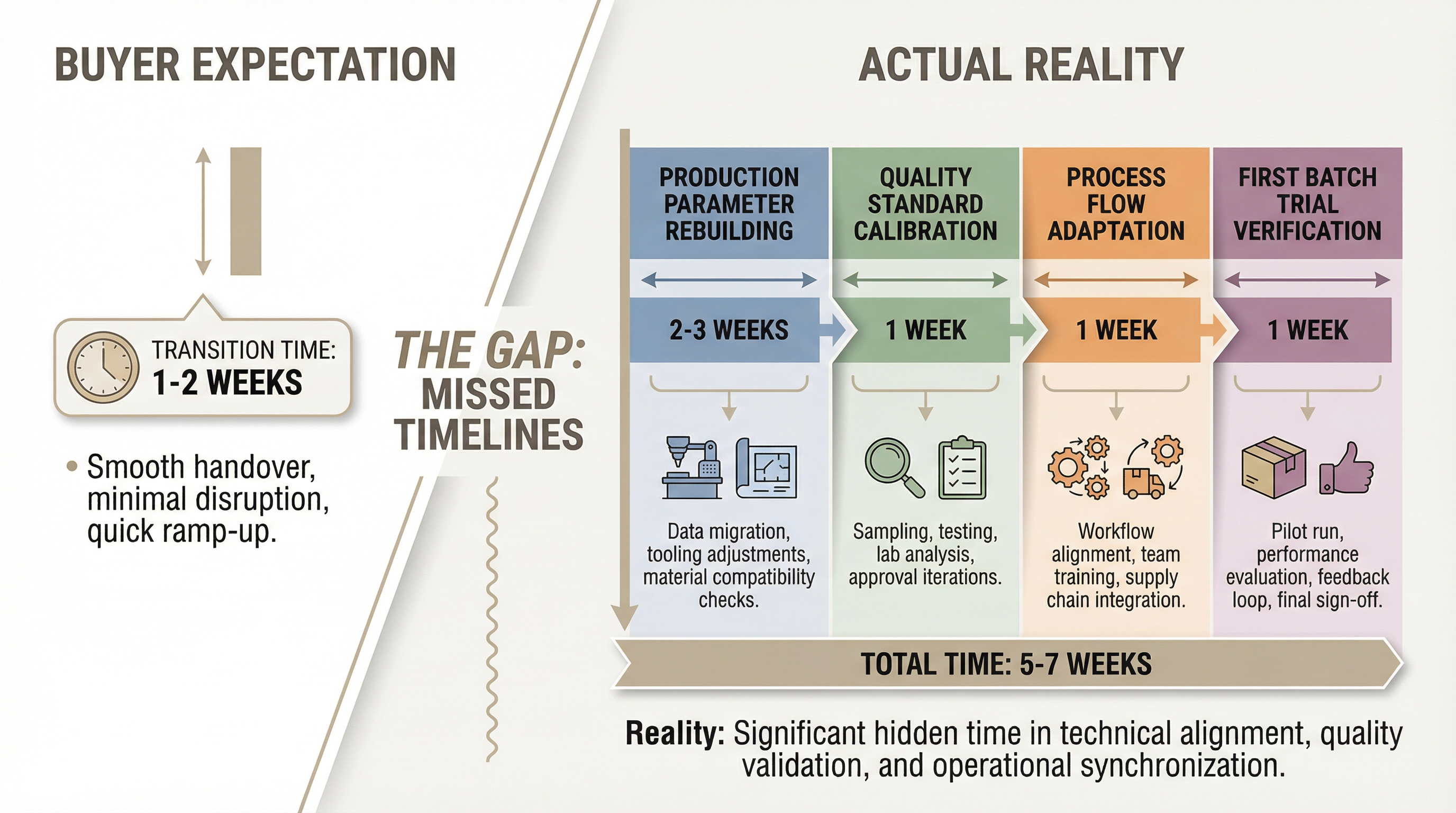

When organisations switch custom drinkware suppliers, they often assume that as long as product specifications remain the same, the new factory can immediately begin production. However, even when technical drawings, material specifications, and quality standards are clearly defined, the new factory must still undergo four stages: production parameter rebuilding, quality standard calibration, process flow adaptation, and first batch trial production verification—typically requiring 3-5 weeks because product specifications and production parameters operate at completely different levels.

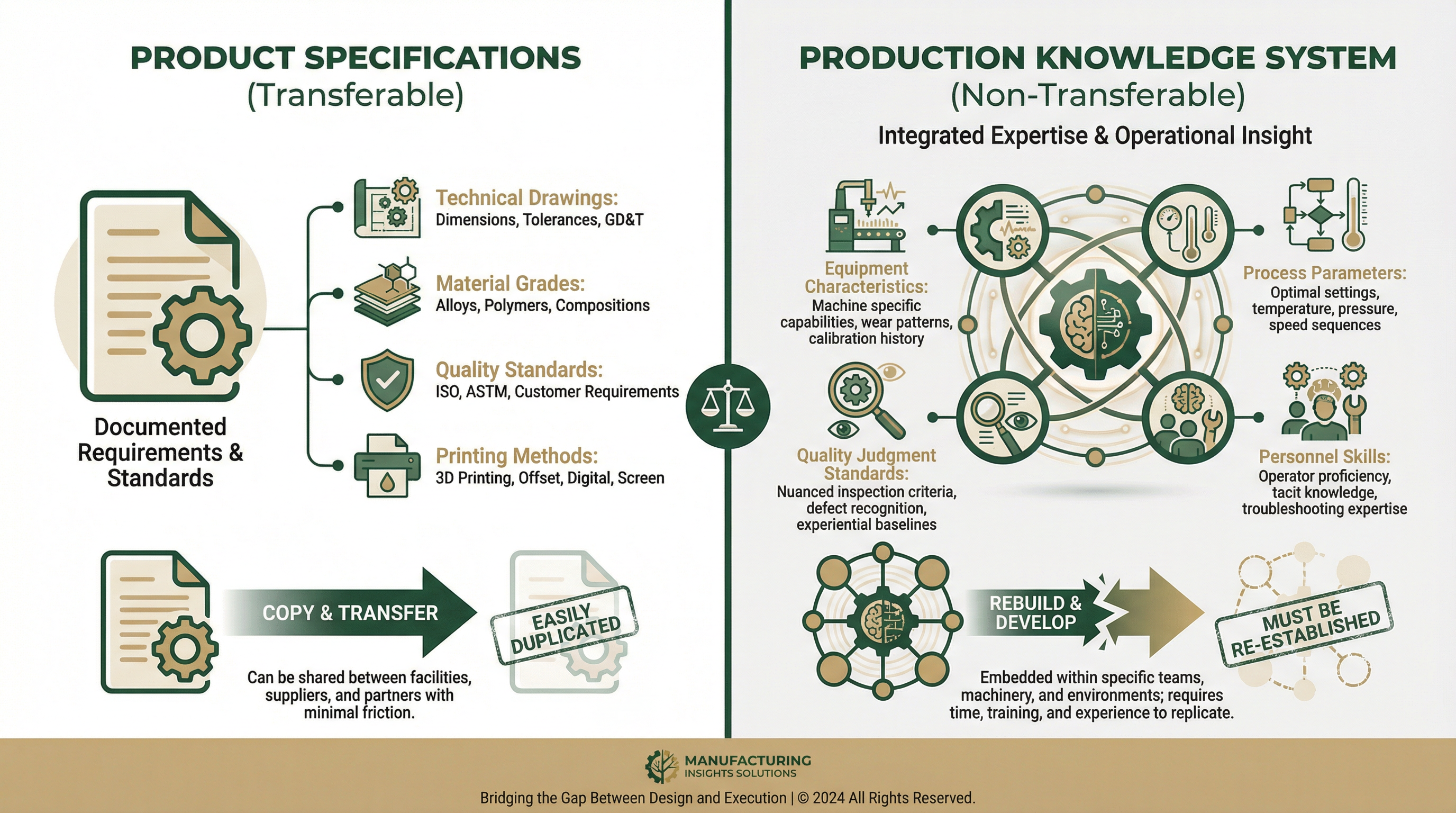

When organisations decide to switch custom drinkware suppliers, procurement teams typically assume that as long as product specifications remain unchanged, the new factory can immediately begin production and lead times should be identical to the original supplier. This assumption is built on seemingly reasonable logic: since technical drawings, material specifications, printing processes, and quality standards have all been clearly defined, the new factory simply needs to execute according to these documents. However, this understanding overlooks a critical fact in manufacturing—product specifications and production parameters operate at completely different levels. The former is the "target description" provided by the buyer, while the latter is the "execution knowledge" internal to the factory, and this execution knowledge cannot be directly transferred through documentation.

Product specifications define "what" needs to be manufactured, including dimensions, material grades, surface treatments, printing methods, quality tolerances, and other quantifiable metrics. These specifications typically exist in the form of technical drawings, bills of materials, and quality inspection standards, and can be transferred between different suppliers. However, production parameters define "how" to manufacture products that meet specifications, including specific settings for each machine, processing sequences, tool selection, operational techniques, and actual execution methods for quality inspection. These parameters are deeply dependent on factory equipment characteristics, production line configurations, and personnel skills. Even if two factories own equipment of the same brand, actual production parameters will still differ due to equipment age, maintenance conditions, and environmental factors. When organisations switch suppliers, product specifications can be completely transferred, but production parameters must be rebuilt from scratch at the new factory, and this rebuilding process typically requires 3 to 5 weeks.

The first stage of production parameter rebuilding is equipment parameter adjustment, which typically requires 2 to 3 weeks. Even if the new factory owns the same model of vacuum forming machines, laser engraving machines, and printing equipment as the original factory, each machine's actual performance will still have subtle differences. For example, after a vacuum forming machine's heating elements have been used for some time, temperature distribution gradually changes, causing the same temperature settings to produce different heating effects on different machines. Technical staff at the original factory may have found the optimal temperature curve for achieving the best forming results on their equipment through multiple trial productions, but this curve cannot be directly applied to the new factory's equipment. The new factory must conduct trial productions anew, observe material deformation at different temperatures, adjust heating times and cooling speeds until finding the optimal parameters suited to their own equipment. This process requires multiple iterations, with each iteration requiring sample production, result inspection, deviation analysis, parameter adjustment, and then another trial production. If the product involves multiple processes, each process requires similar parameter adjustments, and the entire process may require 10 to 15 working days.

Quality standard calibration is the second stage, typically requiring 1 week. Even when buyers provide clear quality inspection standards, such as "vacuum insulation must reach below 0.01 Pa" or "printing pattern colour deviation must be controlled within ΔE 2.0," the new factory still needs to confirm that their testing equipment can accurately measure these metrics and that measurement results are consistent with buyer standards. Different brands or models of vacuum testers may give slightly different readings for the same product due to differences in sensor sensitivity, calibration methods, and environmental compensation algorithms. The new factory needs to compare their testing equipment against buyer-approved standard equipment to confirm that measurement results from both are within acceptable error margins. If deviations are discovered, equipment needs to be recalibrated or measurement procedures adjusted. Additionally, quality inspection is not merely instrument measurement but also includes manual visual inspection, such as checking printing patterns for colour deviation, scratches, bubbles, and other defects. Quality inspectors at different factories may have different judgments about "acceptable defect levels," and the new factory needs to conduct sample comparisons with the buyer to confirm both parties have consistent understanding of quality standards. This calibration process requires multiple communications and sample confirmations, typically requiring 5 to 7 working days.

Process flow adaptation is the third stage, also requiring approximately 1 week. Each factory's production line configuration, material flow, and personnel division of labour differs, and even when producing the same product, actual process flows may vary. For example, the original factory may arrange printing and assembly on the same production line, while the new factory may distribute these two processes across different workshops. Such differences affect semi-finished product storage methods, transportation routes, and process connection times, thereby affecting overall production efficiency and quality stability. The new factory needs to redesign material flows according to their own production line configuration, determine input-output rhythms for each process, arrange personnel work allocation, and conduct actual simulated production to observe whether there are bottleneck stages or quality risks. If problems are discovered, production line configuration or process sequences need adjustment, followed by another verification. This adaptation process requires cross-departmental coordination, including production, quality, logistics, warehousing, and other units, typically requiring 5 to 7 working days to complete.

First batch trial production verification is the final stage, requiring 1 week. After all parameters have been adjusted, the new factory needs to conduct a complete trial production, producing a batch of products matching actual order quantity scale to verify the stability of the entire production process under mass production conditions. The purpose of trial production is not only to confirm that individual products meet specifications but more importantly to confirm that the factory can continuously and stably produce products meeting specifications. For example, the first drinkware's vacuum level may meet standards, but will the 100th and 500th still meet standards? After 8 hours of continuous production, will printing patterns still maintain consistent colour and clarity? These questions can only be discovered under actual mass production conditions. During trial production, buyers typically dispatch quality engineers to the factory site to spot-check samples and confirm quality meets requirements. If any non-conforming items are discovered, production must stop, parameters must be readjusted, and trial production must be conducted again. This verification process typically requires 5 to 7 working days, and if problems requiring readjustment occur, time may be further extended.

These four stages combined typically require 3 to 5 weeks, but when planning supplier switches, buyers often only reserve 1 to 2 weeks of "transition time," believing this is sufficient for the new factory to "familiarise themselves with the product." This misjudgment stems from a simplified understanding of manufacturing, believing that production can immediately begin once drawings and specifications are available. In reality, drawings and specifications are merely the starting point for production. What truly determines whether products can be smoothly mass-produced is the factory's internal production knowledge system that cannot be described in documents. This knowledge system includes actual equipment characteristics, optimal process parameters, quality judgment standards, and personnel operational techniques—all of which need to be re-established at the new factory, and this establishment process cannot be skipped or accelerated.

When organisations plan the lead time structure for custom drinkware, if supplier switching is involved, they must incorporate this 3 to 5 weeks of parameter rebuilding time into overall time planning. If organisations only reserve 1 to 2 weeks of transition time, they will ultimately discover orders delayed by 2 to 3 weeks, or even longer. Worse still, if quality problems are discovered during the first batch trial production requiring parameter readjustment and another trial production, the entire lead time may extend by 4 to 6 weeks. Such delays not only affect organisational market plans but may also lead to contract breaches with customers, causing greater commercial losses.

The method to avoid such misjudgment is to conduct detailed technical exchanges with the new factory before deciding to switch suppliers, understanding how much time they need to rebuild production parameters. Experienced factories will proactively propose conducting pre-trial production, using small batch orders to verify production processes before formal orders begin, confirming all parameters have been adjusted into place. Although such pre-trial production increases upfront costs, it can significantly reduce delay risks for formal orders. Another method is to establish long-term partnerships with new factories rather than frequently switching suppliers. When factories have become very familiar with organisational product specifications, quality requirements, and lead time rhythms, production efficiency for subsequent orders will significantly improve and lead times will become more stable. Frequently switching suppliers, although potentially obtaining lower quotes on individual orders, requires going through the 3 to 5 week parameter rebuilding process each time, which in the long run actually increases overall costs and lead time risks.